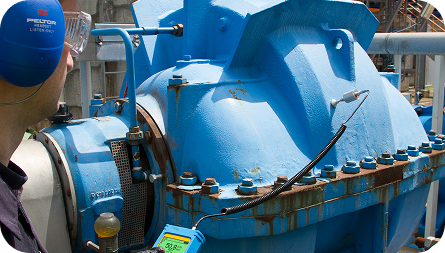

Asset Condition Monitoring

Your Assets are Speaking to you. Our solutions help you listen.

Gain early, effortless, and actionable insights into your mechanical, fluid, and electrical systems with our reliability solutions.

Unplanned equipment failures are costly, dangerous, and disruptive. Traditional inspections often detect problems too late, are overly complicated, or lack the versatility to benefit multiple departments leaving maintenance & reliability teams constantly reactive.

1980 – Advanced Data Collector

SDT pioneered the integration of airborne and structure-borne ultrasound into the first advanced condition monitoring data collector. This innovation has evolved into today’s SDT340, our most advanced multi-functional device yet.

2001 – Precision-Guided Lubrication

SDT introduced structure-borne ultrasound to optimize bearing lubrication, ensuring precision and extended asset life. Today, this innovation has transformed into LUBExpert, the world’s most advanced turnkey solution for managing lubrication programs - and the ON-GUARD, a condition-based automated lubrication system that uses the same intelligence as LUBExpert.

2020 – Acoustic Imaging

SDT was among the first to market with acoustic imaging technology, giving maintenance teams a new way to visualize leaks, electrical faults, and more. In 2025, we released the next generation, delivering higher resolution, farther detection distance, and better sensitivity for more robust reporting.

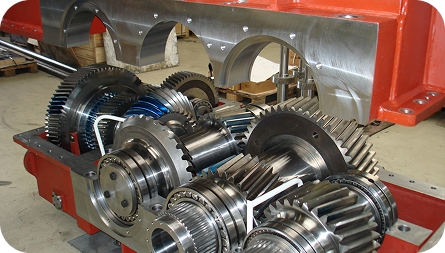

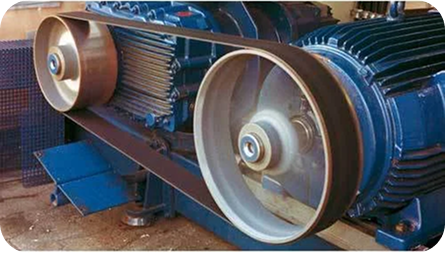

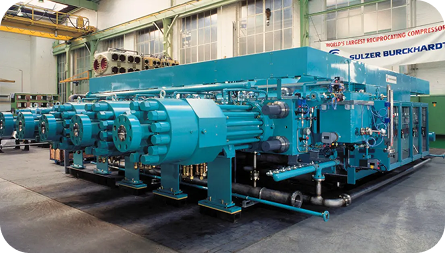

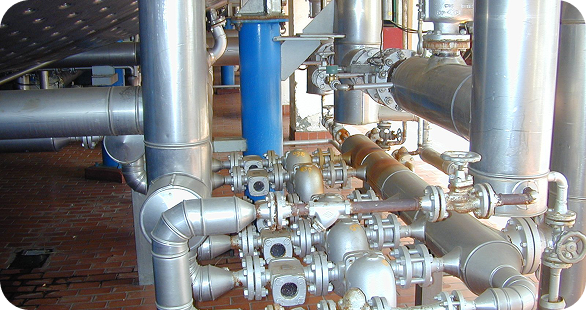

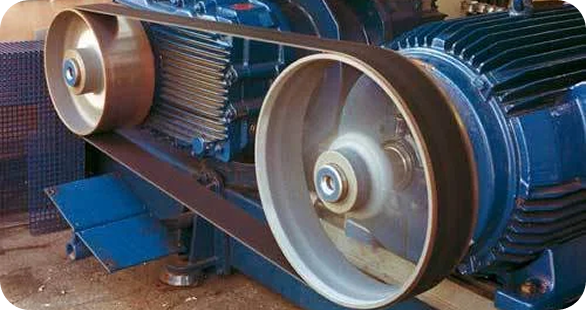

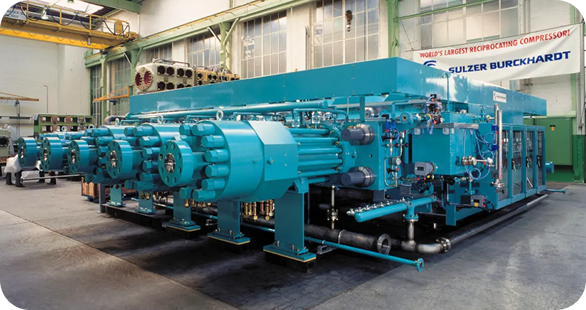

Asset Condition Monitoring

Combine the versatility and early detection capabilities of ultrasound with the diagnostics of vibration analysis for detailed and ensure the full scope of your critical assets remain reliable and efficient.

Asset Condition Monitoring

Combine the versatility and early detection capabilities of ultrasound with the diagnostics of vibration analysis for detailed and ensure the full scope of your critical assets remain reliable and efficient.

How to Launch Your Asset Condition Monitoring Program

01

Define Goals

Decide what success looks like for your organization. Whether it’s extending asset life, improving uptime, or reducing energy waste.

02

Assess Criticality

Identify which assets have the greatest operational impact and failure consequences. Start monitoring these first.

03

Get Expert Guidance

Schedule a consultation with SDT’s reliability specialists to develop a monitoring strategy based on your goals, constraints, and workflows.

04

Find the Right Tools

We’ll help you choose the technologies and workflows that match your team’s skillset, assets, and environment.

05

Measure Success

Track small wins: Fewer production stops and increased energy savings are good insights to build momentum for your program.

Working Together

Gain a better understanding of your asset’s health. Condition monitoring is how leading teams prevent unplanned failures, improve OEE, and build a proactive culture.