While industry embraces automation and predictive maintenance, many organizations still rely on outdated calendar-based lubrication strategies that compromise asset reliability.

Regardless of complexity or correction factors, time-based formulas will eventually lead to over- or under-lubrication.

Thankfully, ultrasound provides a simple, cost effective and easy method for managing and monitoring lubrication tasks

Despite the importance of precision lubrication practices to bearing health, studies show that 80% of premature failures are still lubrication related… Most often caused by over- or under-greasing.

Too much grease… friction and heat increases. But too little will cause undesired metal-on-metal contact.

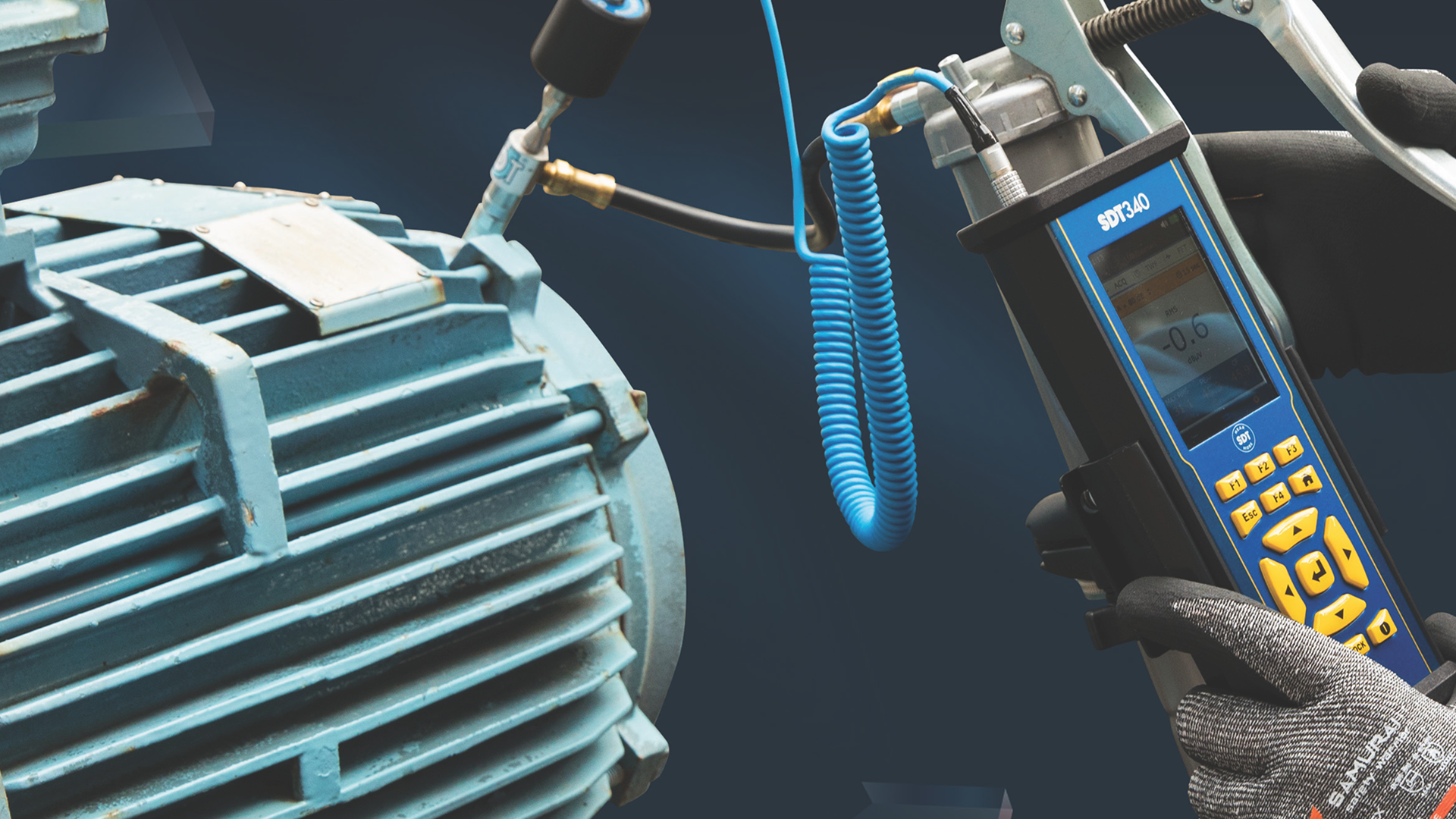

SDT’s lubrication systems solve this by monitoring friction in real time and comparing live data to historic trends, ensuring every bearing receives the optimal amount of grease.

Combining permanent monitoring with automated lubrication delivers clear advantages for critical, hazardous, and remote assets by reducing risk, saving analyst time, and ensuring lubrication is always guided by reliable data.

Handheld instruments remain essential for their flexibility and reach. With handheld devices, inspectors can cover larger areas and numbers of assets at a lower cost point.

But with the right indicators, both handheld devices and permanent systems give reliability teams the clarity they need to make smarter maintenance decisions.

The Four Condition Indicators™ provide simplicity and clarity for ultrasound inspectors and lubrication technicians alike, offering simple, trendable measurements that reveal friction levels and early defect signals.

RMS: Averages the entire sample to capture the overall friction inherent within an asset.

Max RMS: The highest sub-RMSs calculated every 250ms, useful for determining the signal stability

Peak: The maximum value recorded during a measurement, indicating impact severity.

Crest Factor: Ratio of Peak to RMS. Useful for indicating the severity of defects.