SDT340

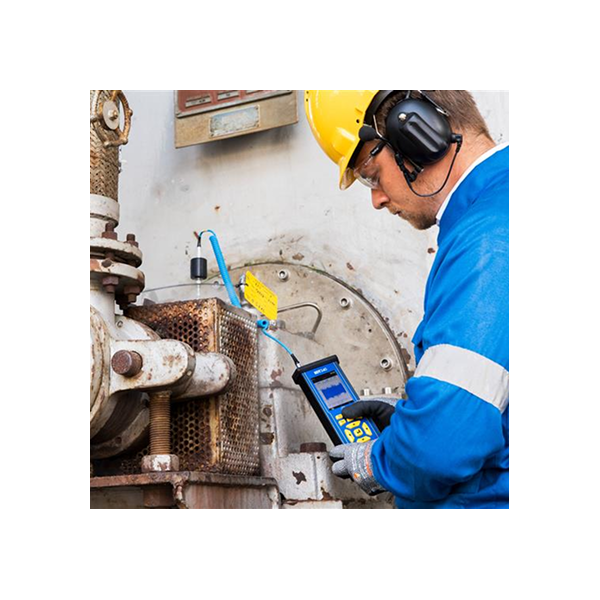

Advanced Ultrasound & Vibration Condition Monitoring Data Collector

Starting at:

$13,995

Organizations that trust the SDT340 gain a better understanding of the health of their factory by combining ultrasonic trending, vibration analysis, and temperature/tachometer measurements to completely capture their asset’s condition.

Ultrasound delivers quick wins by identifying failures early, before they become costly breakdowns. From bearing failures to electrical faults, ultrasound reduces downtime, waste, and unplanned repairs, often paying for itself within months.

We’ve had customers find and fix compressed air and gas leaks on day-one, that were waste tens of thousands of dollars in energy.

Ultrasound is incredibly versatile. Beyond bearing monitoring, you can use it to detect compressed air and gas leaks, inspect steam traps, identify electrical faults like arcing and tracking, and even verify valve function.

This one device supports multiple condition monitoring tasks across your facility.

Not at all. Ultrasound is the easiest predictive maintenance technology to implement thanks to its simplicity and versatility across applications. SDT’s solutions are intuitive, user-friendly, and require minimal training.

With audible and visual feedback, built-in analysis tools, and free implementation training, your team can start locating leaks, detecting bearing issues, electrical issues, and more… right out of the box.

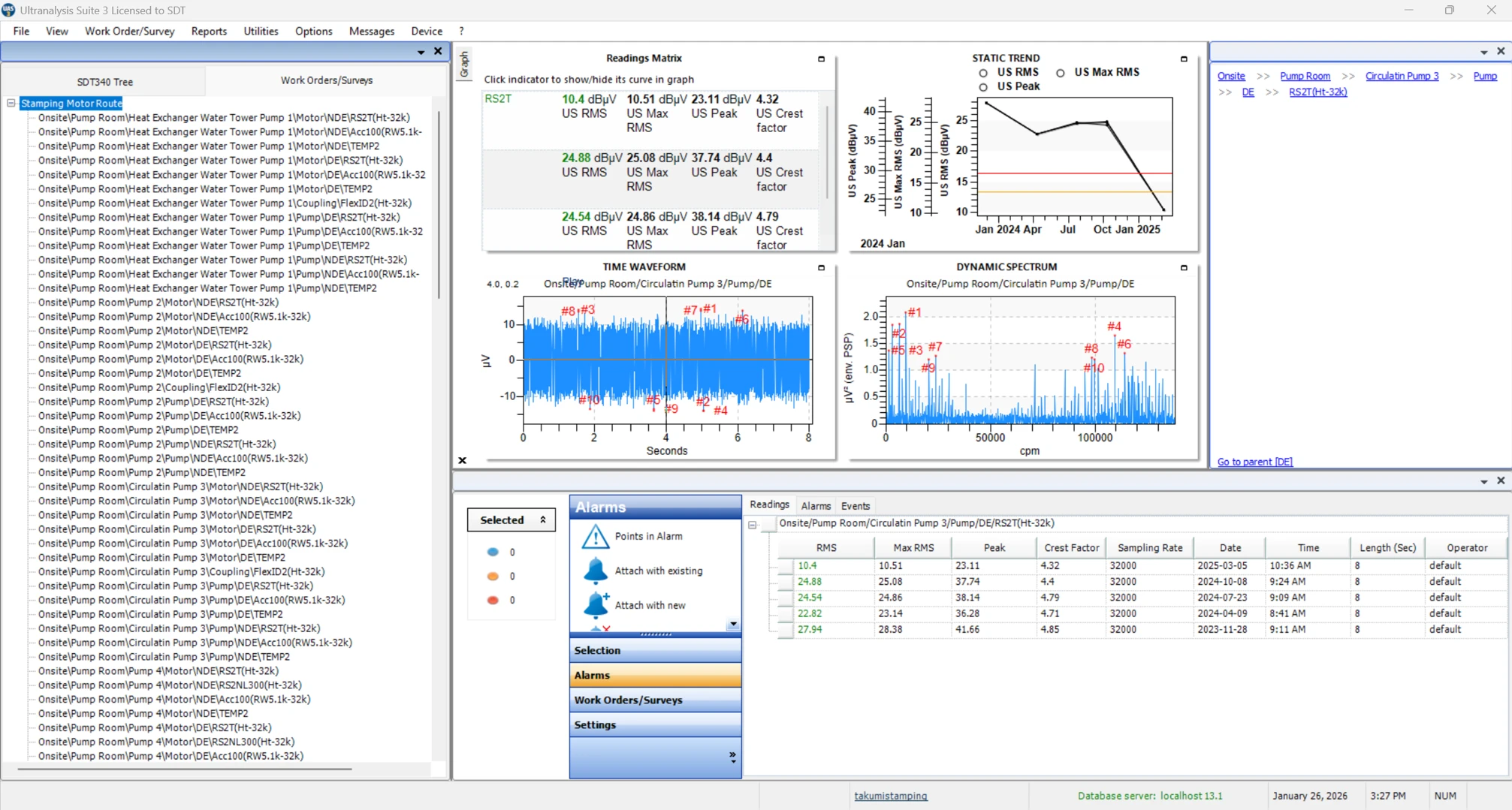

The Most Advanced Ultrasound Analysis Software Ever Written

The SDT340’s union with UAS3 was transformative for ultrasound condition monitoring, creating a seamless workflow that bridges the gap between data collection and analysis.

This full integration allows for access to critical information in the field and enables users to efficiently manage, assess, and act on asset performance in real-time.

Smooth Workflow for Route-Based Inspections

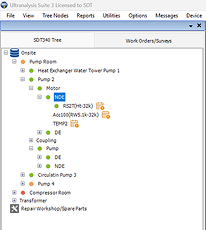

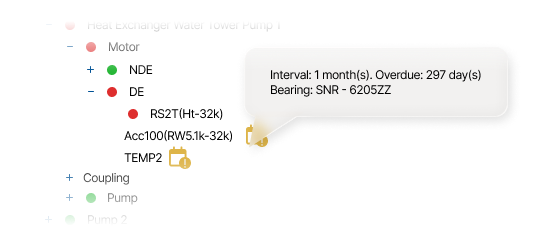

Tree Structured Database

A tree structured database organizes condition monitoring routes and inspection points across your facility.

Navigational Images

Use visual references to easily locate and track inspection points along your condition monitoring routes.

Connected Workflow

Routes made in UAS3 and executed with the SDT340 ensure a structured workflow, guiding users through inspection points for consistency and efficiency.

Ultrasound & Vibration Analysis Multi-Functionality

Monitor the health of your critical assets with airborne & contact ultrasound, vibration, temperature, and tachometer measurement capabilities.

Compatible with SDT's 2nd Gen Sensors

With the SDT340, inspectors gain unparalleled flexibility across applications without changing platforms.

Contact Ultrasound Inspection

Detect mechanical failures early with structure-borne ultrasound. The SDT340 detects subtle changes in friction, impacting, and lubrication conditions, long before vibration or temperature thresholds are exceeded.

Airborne Ultrasound Inspection

Inspect assets you can't or shouldn't touch with airborne ultrasound to gain immediate insight. This is particularly useful when inspecting electrical assets or searching for leaks but can also be used to check couplings, conveyors, belts, etc.

Vibration Analysis

With built-in vibration analysis, the SDT340 lets inspectors look at the same problem from more than one angle. That added context helps confirm developing faults and supports a more well-rounded condition monitoring program.

Temperature & Tachometer

Temperature and speed matter when you’re interpreting condition data. The SDT340 captures both, giving inspectors the context needed to trust what their data is saying. Useful for steam traps, electrical assets, and rotating equipment.

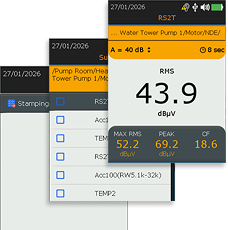

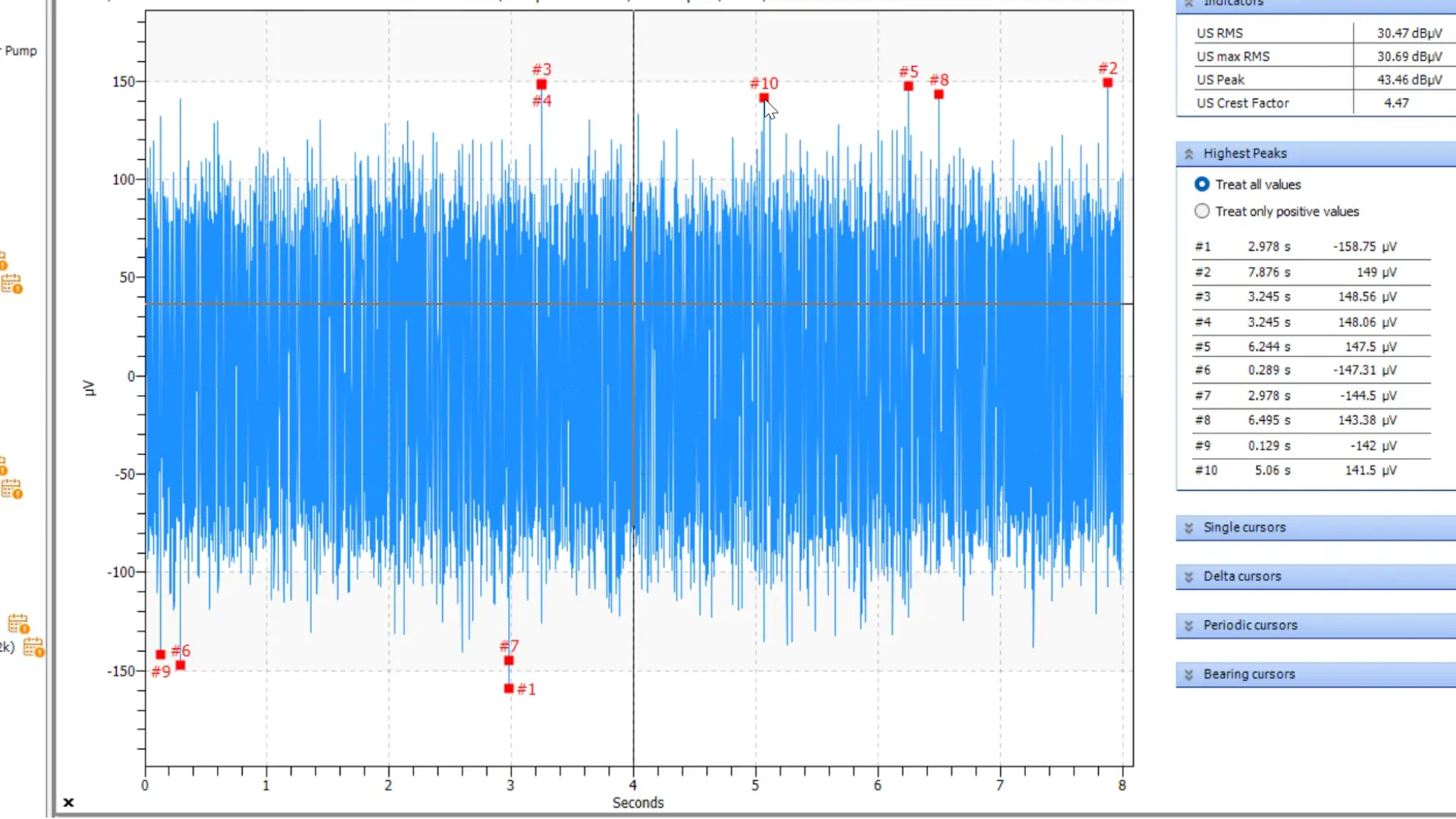

Four Condition Indicators

Log these four KPIs; RMS, Max RMS, Peak, and Crest Factor with every reading.

Averages the entire sample to capture the overall friction inherent within an asset.

The highest sub-RMSs calculated every 250ms, useful for determining the signal stability.

The maximum value recorded during a measurement, indicating impact severity.

Ratio of Peak to RMS. Useful for indicating the severity of defects.

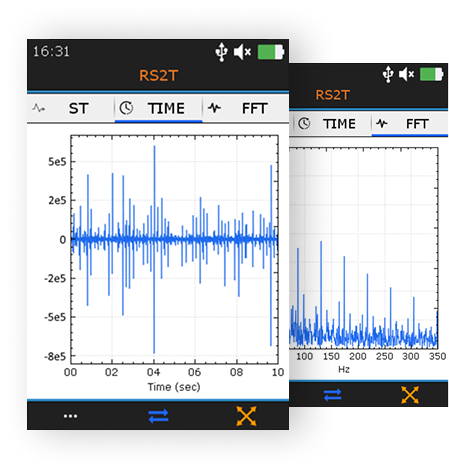

On-Screen Analysis

Visualize both time and spectral waveforms in real-time for faster diagnostics and to support in-field decision making.

Precision Diagnostic Features

The SDT340's high sampling rate of up to 256k samples per second, making it perfect for detailed diagnostics like lubrication assessment, cavitation detection, and finding the earliest signs of deterioration on rotating assets.

Smooth Workflow for Route-Based Inspections

Bluetooth Connectivity

Eliminate cable clutter near rotating assets for a smoother, safer, and more efficient inspection experience.

10-Minute Measurement Acquisition Time

Record up to 10 minutes of continuous condition monitoring data, perfect for slow-speed bearing monitoring.

Custom Messaging

Contextualize measurements with messages that sync between the SDT340 & UAS3 for better maintenance decisions.

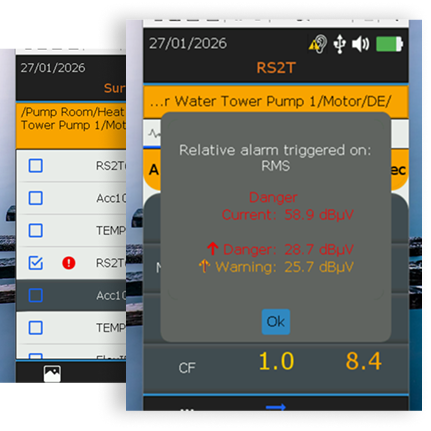

Alarms

Safe, relative, and absolute alarms alert you when data indicates the need for action. Color coded thresholds and clear visuals make it easy to prioritize what matters.

Data Collection Compliance

The SDT340 & UAS verifies that required measurements are taken to maintain accuracy, consistency, and program integrity.

Asset Condition Monitoring Applications

Ultrasound condition monitoring provides reliability teams with the earliest possible warning signs of rotating asset degradation, allowing for the maximum amount of time to plan & perform maintenance interventions and order necessary spares.

A combination of airborne and contact ultrasound monitoring techniques help inspectors monitor bearings, motors, pumps, couplings, belt driven systems, fans, conveyors and more.

Recent changes to NFPA70B mandate the use of predictive maintenance inspection on all electrically charged systems. Ultrasound’s ability to detect a wide range of defects in their early stages is why it is outlined by the NFPA as an inspection technology.

Ultrasound excels at detecting medium & high-voltage electrical system defects like arcing, tracking, corona, and partial discharge. Improve electrical asset reliability and reduce safety hazards with ultrasound monitoring.

Air, gas, and vacuum leaks waste energy, strain equipment, and drive-up costs. In noisy industrial environments, these leaks go unnoticed, reducing efficiency and reliability.

The SDT340 cuts through the noise, pinpointing leaks with precision. Locate, tag, and repair leaks to boost efficiency, sustainability, and system reliability. Stop wasting resources… Detect and fix leaks before they drain your bottom line.

Over & under lubrication are the leading cause of bearing failure and up to 80% of premature bearing failures can be attributed to poor lubrication practices. Mitigate the guesswork, and ensure grease is only applied when needed.

The SDT340 lets you monitor bearing friction in real time, preventing damage and waste. Grease with precision, extend asset life, and keep your equipment running smoothly.

Failed steam traps waste energy, reduce system efficiency, and can lead to costly water hammer and corrosion.

Ultrasound testing can help identify mechanical failures, cold traps, and blow-through conditions in as little as one cycle.

Valves are critical control points in every process system, and when they fail, energy, product, and efficiency are lost.

The SDT340 detects the full range of valve failure modes—including internal and external leakage, cavitation, seat wear, sticking, and flow restriction.

Starting a Condition Monitoring Program

01

Define Goals

What’s important to you and your organization? What does a successful condition monitoring program look like?

02

Assess Criticality

Identify which assets are most vital, and where ultrasound or vibration monitoring has the biggest impact.

03

Get Expert Guidance

Find a solutions provider that connects you with the right tools and guidance to reach your goals and address challenges.

04

Record and Report Wins

Start documenting early successes to build momentum, demonstrate the value of your program, and secure stakeholder buy-in.

Working Together

Spend less time reacting to breakdowns and more time preventing them.

Partnering with SDT Ultrasound Solutions

SDT Ultrasound Solutions has been supporting industry for more than 50 years, helping organizations around the world get more out of their condition monitoring equipment and reliability strategy.

Our purpose-built solutions, training, and services empower you to reduce unplanned downtime, optimize maintenance schedules, and protect your mission-critical equipment.

When you partner with SDT Ultrasound, you gain more than a vendor. You gain a proactive partner prepared to support your reliability journey with the tools, training, and partnership needed for success.